In recent

years, with the continuous increase in labor costs and the increasing

requirements for product quality, many electronics companies are facing

unprecedented market pressure. Establishing a highly automated and informatized

control system can not only help electronic companies reduce labor costs and

improve production efficiency, but also realize enterprise information

management, significantly improve the market competitiveness of enterprises,

and complete the transformation of enterprises into high-end manufacturing.

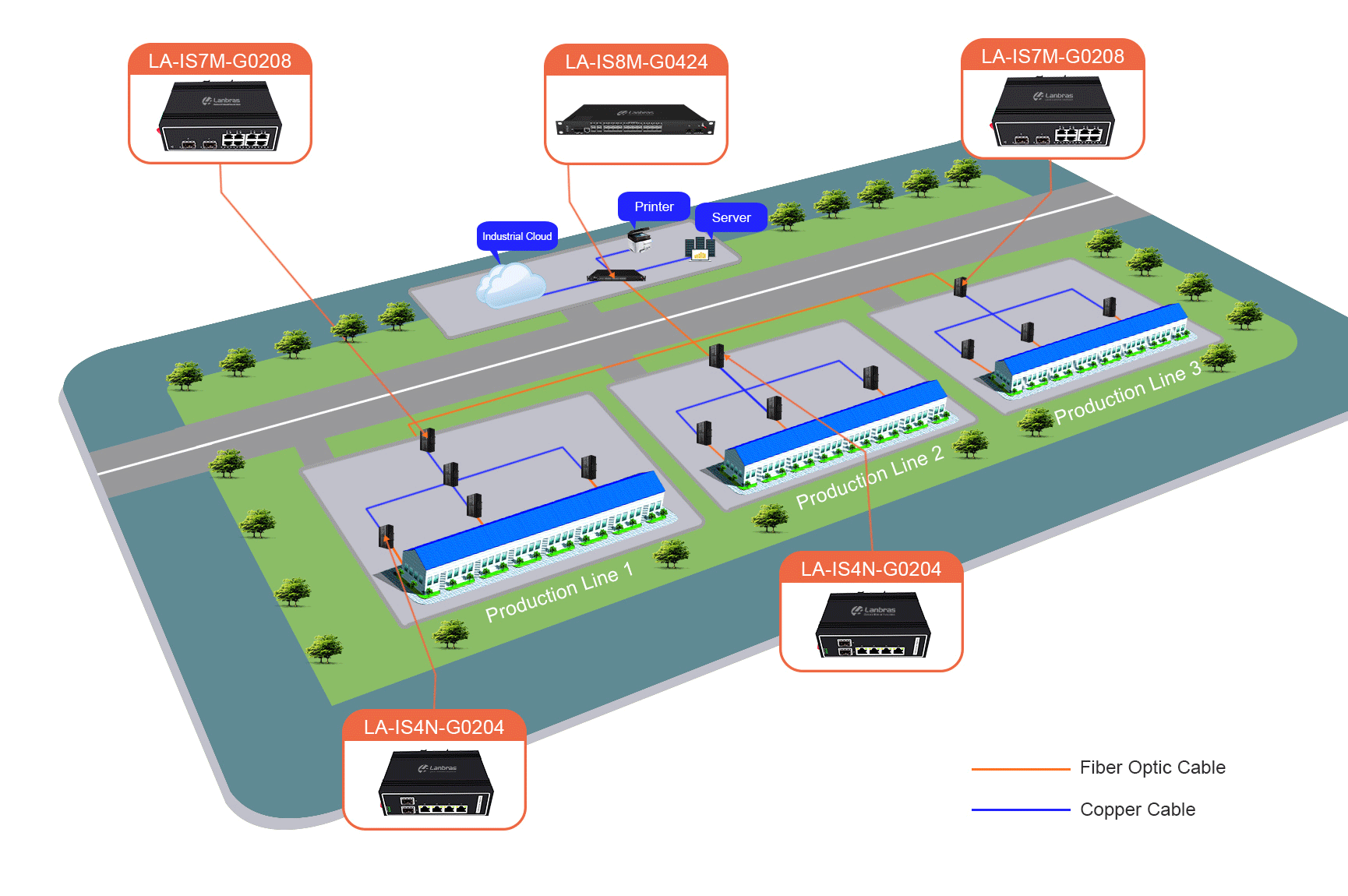

However, to build up well-connected and beneficial networks in factory plants faces several problems. Firstly, some factory plants such as steel or automobile factory are exposed in the environment with dusts, high moisture, humidity and even higher temperature. Secondly, some legacy machines in factory plants only support serial protocol in Industrial Automation applications. Therefore, it is vital to choose network devices that can support both serial and Ethernet-based connections. To reduce downtime and enhance productivity, it is also important to take redundant mechanism into consideration. All in all, to set up a successful network system in factory plants, there are several challenges that we may face and need to be handled with caution.

contact us

Copyright © 2017-2023 Lanao Communication Technology Co., LTD. All Rights Reserved.