As we move further into the digital era, industries are undergoing rapid transformations. The automation, digitization, and smart manufacturing trends that once seemed distant are now reality. One of the premier events driving this change is the SPS (Smart Production Solutions) exhibition, which will be held in Nuremberg, Germany, in 2025. The event is set to be a beacon for cutting-edge technologies in industrial automation, and for businesses like Lanaotek, which operates in the high-tech telecom and optical communications field, the solutions presented at SPS 2025 will provide invaluable insights and tools to enhance productivity, efficiency, and competitiveness.

This article explores the key highlights of SPS 2025, how Smart Production Solutions are set to revolutionize industries, and why it matters for the future of businesses such as Lanaotek.

The Shift Towards Smart Manufacturing

The advent of smart manufacturing represents a new industrial revolution where machines and systems are interconnected through the Internet of Things (IoT), enabling intelligent data exchange and automated decision-making, facilitated by reliable industrial router supplier solutions. The goal is simple: to create more flexible, efficient, and responsive production processes.

At SPS 2025, companies from around the world will showcase technologies that are advancing this shift, particularly in areas such as industrial automation, robotics, AI-based analytics, and digital twins. These technologies enable manufacturers to make faster decisions, optimize operations, reduce costs, and improve product quality.

Smart factories, powered by advanced automation and real-time data analysis, are becoming the backbone of modern industrial processes. By integrating machine learning, AI, and advanced robotics, manufacturers can adapt more swiftly to market demands, making production processes far more agile than ever before.

The Role of AI and Machine Learning in SPS 2025

Artificial Intelligence (AI) is playing an increasingly vital role in transforming traditional manufacturing systems into smart ones. By analyzing massive volumes of data, AI can predict failures, suggest optimizations, and enable machines to communicate with each other autonomously.

Machine learning algorithms in production lines, for example, can predict maintenance needs, which reduces downtime and enhances efficiency. Moreover, AI-powered inspection systems can detect defects in products at a much higher accuracy than human workers, ensuring product quality is maintained across large volumes of production.

At SPS 2025, leading companies will display AI-powered tools that improve process management, supply chain optimization, and quality assurance. These innovations will not only help manufacturers save on costs but also increase flexibility, which is particularly crucial for industries like telecommunications and optical communications, where technological advancements evolve rapidly.

The Role of Robotics and Automation

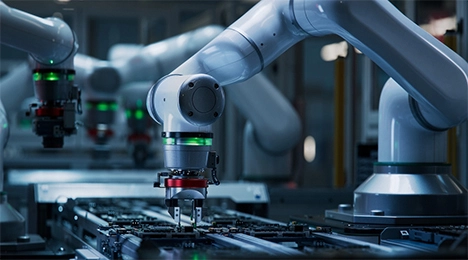

Robotics has long been at the forefront of industrial innovation, and SPS 2025 is no exception. Advanced robotics systems that are smarter, more efficient, and more adaptable will be showcased, covering a wide range of applications in manufacturing.

Collaborative robots, or "cobots," are one of the major trends expected at the event. These robots are designed to work alongside human workers, enhancing their capabilities and ensuring tasks are completed faster and more safely. Cobots are capable of performing repetitive and physically demanding tasks, allowing human workers to focus on higher-value activities.

In industries like optical communications, where precision and speed are paramount, the integration of robotics into production processes is already proving beneficial. Automated assembly lines, capable of handling delicate components such as optical transceivers, allow for better consistency and faster production times.

Digital Twins and Virtualization

The concept of digital twins-virtual representations of physical assets-will be another significant topic at SPS 2025. By simulating real-world processes in a digital environment, manufacturers can model complex production lines and predict how systems will behave under different scenarios.

Digital twins enable businesses to monitor production, optimize operations, and perform predictive maintenance without disrupting the real-world environment. For companies like Lanaotek, which deals with highly complex telecommunication products like optical modules, switches, and cables, the ability to simulate and optimize the entire production cycle will offer a huge advantage in reducing waste and improving efficiency.

Moreover, digital twins help in creating smarter supply chains. With real-time data tracking and simulation, businesses can better understand their production flows, forecast demand, and anticipate problems before they occur.

Edge Computing: The Next Step in Industrial IoT

As part of the move toward Industry 4.0, edge computing is becoming a critical component in smart manufacturing. With edge computing, data is processed locally on machines rather than being sent to the cloud. This allows for faster decision-making, as well as reduced latency, which is especially crucial in industrial settings where real-time processing is key to preventing downtime.

SPS 2025 will showcase edge computing solutions that help businesses process data at the point of action. These technologies will enable companies to make critical decisions in real time, optimizing production lines, improving safety, and reducing downtime.

For businesses such as Lanaotek, which provide telecommunications infrastructure products, edge computing can be used to monitor and manage network components in real-time, ensuring seamless connectivity and reliability. This has significant implications for industries that rely heavily on uptime, such as telecommunications and data centers.

The Smart Factory and Supply Chain Integration

A key takeaway from SPS 2025 is the growing need for manufacturers to integrate smart factories with intelligent supply chains. Smart factories don't just rely on automation for internal processes; they also rely on real-time data sharing across the entire supply chain. This ensures that manufacturers can respond quickly to changes in demand, manage inventories efficiently, and reduce the risk of stockouts or overproduction.

For telecom and optical communication companies like Lanaotek, the ability to integrate a smart factory approach into their production processes and supply chain management will be critical. By connecting production schedules with real-time supply chain data, Lanaotek can ensure they meet client demand without overstocking or causing delays in delivery.

As a leading player in the optical communications and telecommunication sector, Lanaotek stands at the crossroads of these technological advancements. The smart solutions featured at SPS 2025 will directly influence the development of next-generation products, systems, and networks that are critical to maintaining the company's competitive edge in the global market.

Lanaotek's portfolio of products-ranging from optical modules, cables, and industrial switches to advanced IoT solutions-will benefit significantly from the advancements showcased at SPS 2025. As smart manufacturing technologies like AI, robotics, and digital twins become mainstream, the company will be able to leverage these innovations to enhance its product offerings, streamline production processes, and ensure product quality.

Furthermore, the integration of advanced supply chain solutions will enable Lanaotek to optimize procurement, inventory management, and distribution processes, ensuring they can continue to offer high-quality, reliable products to customers around the world.

Visit www.lanaotek.com to explore our comprehensive range of products and learn more about how we’re contributing to the future of telecommunications and optical communications.

By Jennifer Tseng

Hi, I'm Jennifer, Marketing Executive at lanaotek.com.

I specialize in translating cutting-edge optical and Ethernet transmission technologies into clear, valuable insights that help our customers stay ahead in a fast-evolving digital world.

By turning complex technical concepts into practical, business-driven content, I aim to empower decision-makers with the knowledge they need to make confident, future-ready choices.

Internet Data Center

Internet Data Center FAQs

FAQs Industry News

Industry News About Us

About Us Data Center Switch

Data Center Switch  Enterprise Switch

Enterprise Switch  Industrial Switch

Industrial Switch  Access Switch

Access Switch  Integrated Network

Integrated Network  Optical Module & Cable

Optical Module & Cable

Call us on:

Call us on:  Email Us:

Email Us:  2106B, #3D, Cloud Park Phase 1, Bantian, Longgang, Shenzhen, 518129, P.R.C.

2106B, #3D, Cloud Park Phase 1, Bantian, Longgang, Shenzhen, 518129, P.R.C.