In today's fast-paced industrial environments, the demand for robust and reliable network infrastructure is at an all-time high. Whether in manufacturing, transportation, or energy sectors, industrial applications require seamless connectivity and real-time data flow. Enter the Lanbras Din-Rail Layer 3 Managed Switch, a device that’s designed to meet these critical needs. This article delves into the key features and benefits of these switches, explaining why they are indispensable for modern industrial networks.

What is a Lanbras Din-Rail Layer 3 Managed Switch?

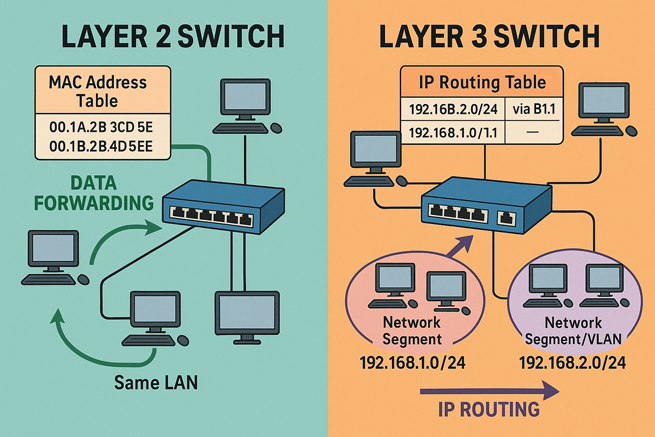

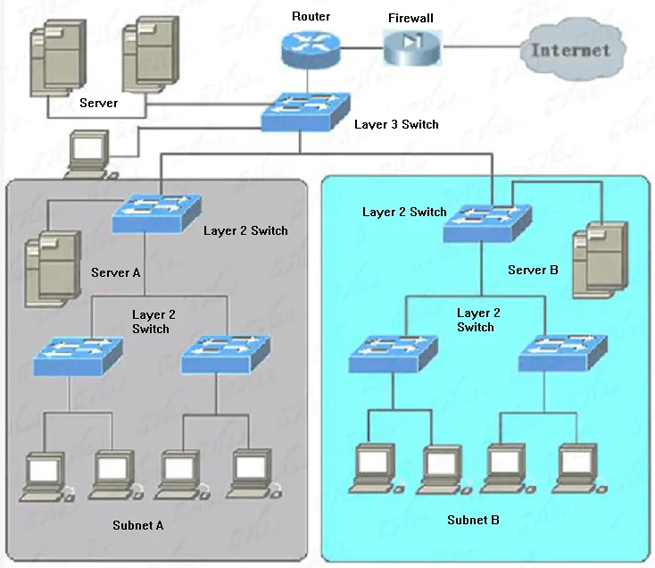

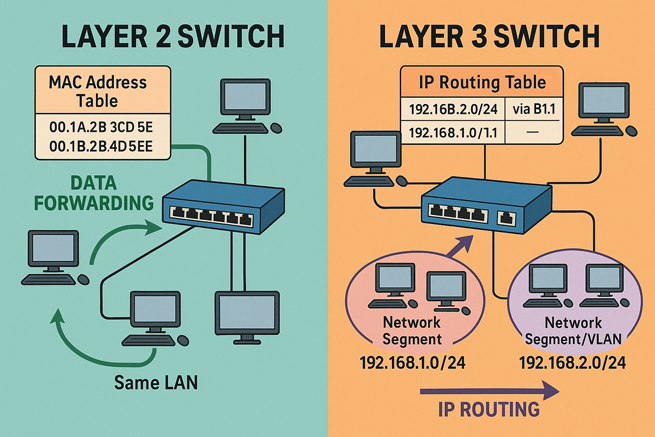

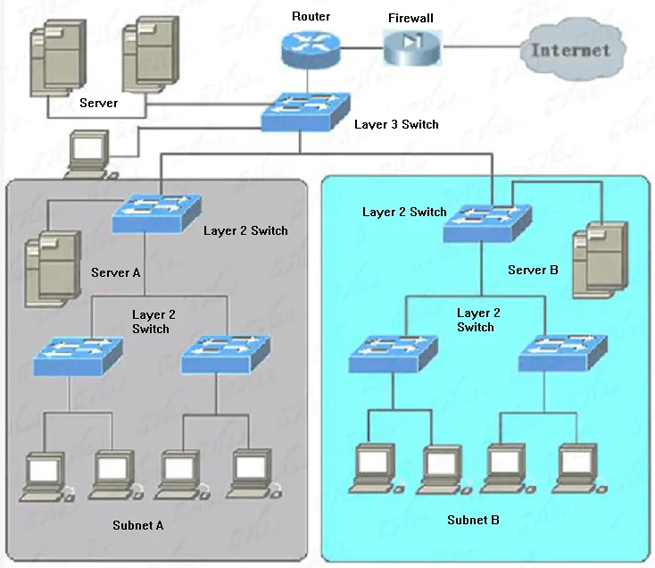

A Lanbras Din-Rail Layer 3 Managed Switch is a versatile, high-performance networking device designed to provide advanced routing capabilities and scalable network management, all while being mounted on a standard DIN rail. These switches are engineered to perform well in harsh industrial environments where space is limited, and reliability is paramount, a key benefit of using a robust din rail managed switch. By offering the capability to manage Layer 3 routing, they bridge the gap between basic Layer 2 switches and full-fledged routers.

Unlike traditional unmanaged switches, Layer 3 Managed Switches allow network engineers to create routing tables, control traffic, and optimize data flow with greater precision. When integrated with industrial automation systems, they enable businesses to achieve faster communication between devices, ensuring efficient and error-free operations.

Why Choose Lanbras Din-Rail Layer 3 Managed Switches?

1. Rugged Industrial Design

One of the key advantages of Lanbras Din-Rail switches is their design for tough industrial settings. They are built to withstand temperature fluctuations, humidity, and electromagnetic interference—common issues in manufacturing plants, oil rigs, and other harsh environments. The DIN rail form factor ensures quick installation and maintenance, reducing downtime.

2. Layer 3 Routing Capabilities

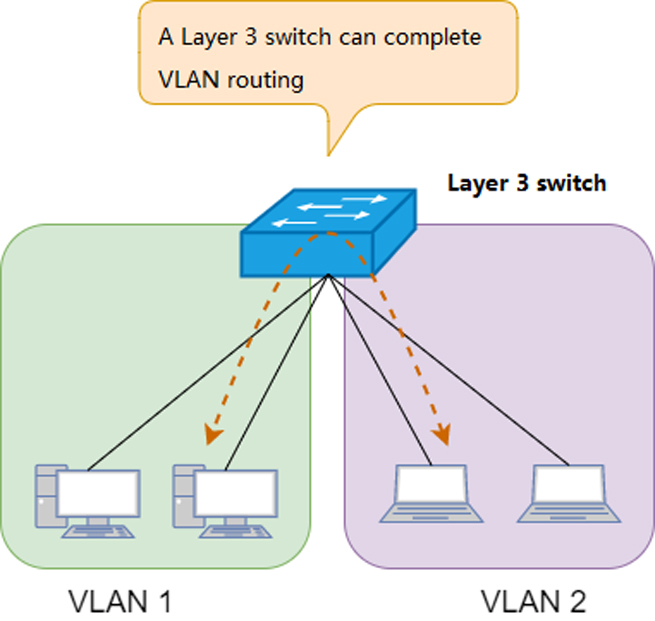

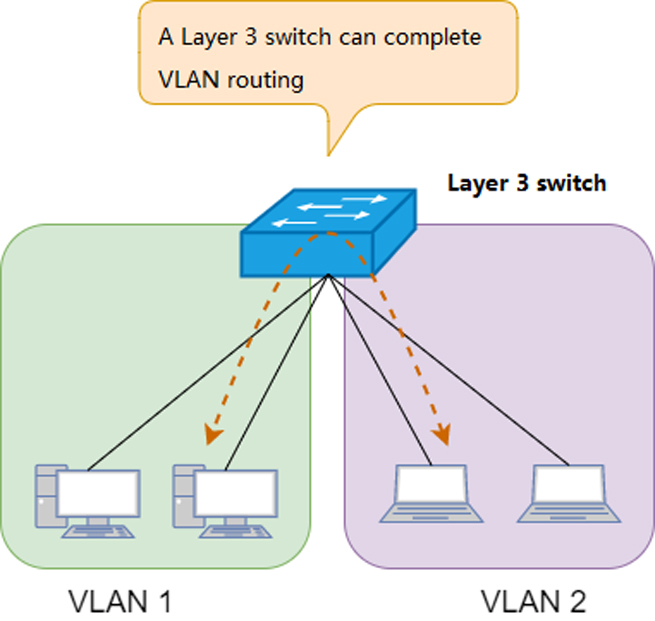

The Layer 3 functionality of these switches allows for inter-VLAN routing, enabling traffic management between different network segments. This is particularly useful in large industrial networks where multiple devices and systems need to communicate over different VLANs (Virtual Local Area Networks). Layer 3 routing enables devices in different segments to exchange data without overloading the core network.

3. Advanced Network Management

As managed switches, these devices offer extensive features for network monitoring and optimization. Network administrators can configure, monitor, and troubleshoot networks remotely via an intuitive interface. This level of control ensures that any network disruptions or performance issues are quickly detected and addressed.

4. Powerful QoS and Security Features

The Lanbras Din-Rail Layer 3 switches come equipped with advanced Quality of Service (QoS) protocols, ensuring that high-priority traffic such as real-time communications and critical data is given precedence over less critical traffic. Additionally, security features like port security, IP-MAC binding, and access control lists (ACLs) are built-in to protect against unauthorized access and network attacks.

5. Scalability and Flexibility

Industrial operations often grow over time, necessitating network expansion. These switches provide scalable solutions that allow for easy integration with additional network devices, whether it’s more switches, routers, or end-user devices. Their flexibility ensures that businesses can keep up with growing demands without needing to overhaul their network infrastructure.

Applications of Lanbras Din-Rail Layer 3 Managed Switches

1. Smart Manufacturing Systems

In smart factories, Lanbras Din-Rail Layer 3 Managed Switches play a crucial role in connecting IoT devices, sensors, PLCs (Programmable Logic Controllers), and other automated machinery. With real-time communication and data transfer, these switches ensure that industrial processes are efficient, responsive, and optimized for minimal downtime.

2. Transportation Networks

From controlling traffic lights to managing train signaling systems, Lanbras Din-Rail Layer 3 Managed Switches support critical infrastructure in transportation. Their ability to handle large amounts of traffic and ensure seamless data flow makes them essential for ensuring safety and coordination in transportation networks.

3. Energy and Utilities

The energy sector, particularly in remote or challenging environments, relies on reliable communications to monitor power grids, turbines, and substations. Lanbras Din-Rail Layer 3 Managed Switches enable quick communication between control centers and field equipment, facilitating the monitoring of systems in real-time and improving operational efficiency.

Key Considerations When Selecting Lanbras Din-Rail Layer 3 Managed Switches

When choosing a Lanbras Din-Rail Layer 3 switch for an industrial environment, there are several factors to keep in mind:

Environmental Suitability: Ensure the switch can handle the operating temperature and environmental conditions of your industry.

Port Density: Determine how many ports are needed to accommodate your devices. Some switches offer additional SFP (Small Form-factor Pluggable) ports for fiber-optic connectivity.

Network Speed: Depending on the scale of your operation, you may need Gigabit or 10-Gigabit Ethernet ports to handle higher data throughput.

Redundancy and Reliability: Look for features such as dual power inputs and redundant fans to minimize the risk of network failure.

Lanbras Din-Rail Layer 3 Managed Switches provide a reliable, scalable, and secure networking solution for industrial applications. With their advanced routing capabilities, robust design, and flexible management features, these switches are the backbone of modern industrial networks. Whether you're managing a smart factory, a transportation hub, or a power grid, these devices ensure seamless communication and operational efficiency.

Integrating a Lanbras Din-Rail Layer 3 Managed Switch into your industrial network can unlock a range of benefits, from real-time data exchange to enhanced security, all while ensuring that your infrastructure is future-ready. With the continuous evolution of industrial automation, these switches are becoming a vital part of ensuring connectivity and reliability at every level of operation.

By Jennifer Tseng

Hi, I'm Jennifer, Marketing Executive at lanaotek.com.

I specialize in translating cutting-edge optical and Ethernet transmission technologies into clear, valuable insights that help our customers stay ahead in a fast-evolving digital world.

By turning complex technical concepts into practical, business-driven content, I aim to empower decision-makers with the knowledge they need to make confident, future-ready choices.

Internet Data Center

Internet Data Center FAQs

FAQs Industry News

Industry News About Us

About Us Data Center Switch

Data Center Switch  Enterprise Switch

Enterprise Switch  Industrial Switch

Industrial Switch  Access Switch

Access Switch  Integrated Network

Integrated Network  Optical Module & Cable

Optical Module & Cable

Call us on:

Call us on:  Email Us:

Email Us:  2106B, #3D, Cloud Park Phase 1, Bantian, Longgang, Shenzhen, 518129, P.R.C.

2106B, #3D, Cloud Park Phase 1, Bantian, Longgang, Shenzhen, 518129, P.R.C.