What are Industrial Switches?

Industrial switches are networking devices designed to support industrial environments where devices and networks need to perform under harsh conditions. These switches are built to handle extreme temperatures, vibrations, dust, and moisture, offering reliability in manufacturing floors, outdoor settings, and other rugged conditions. They are often used in applications like factory automation, transportation, and smart grids, where consistent and secure data transmission is essential.

How are Industrial Switches different from regular switches?

Unlike regular switches that are designed for office or home environments, industrial switches are engineered for durability, higher reliability, and resistance to extreme conditions. They typically offer features like extended temperature ranges, ruggedized enclosures, higher MTBF (Mean Time Between Failures), and support for industrial protocols like Modbus or PROFINET. This makes them ideal for environments subject to vibrations, power surges, or extreme temperatures.

What are the main types of Industrial Switches?

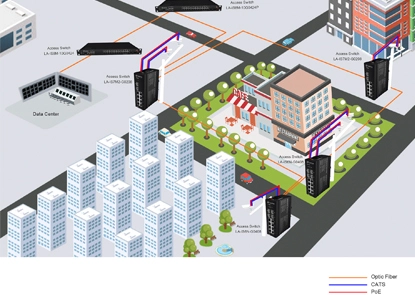

The main types of industrial switches include unmanaged switches, managed switches, PoE (Power over Ethernet) switches, and fiber optic switches. Unmanaged switches provide basic functionality without configuration, while managed switches allow for advanced configurations and monitoring. PoE switches supply power to devices like IP cameras and access points over Ethernet, and fiber optic switches are designed for high-speed, long-distance data transfer via fiber optics.

What industries use Industrial Switches?

Industrial switches are used in a variety of sectors, including manufacturing, energy (renewable and non-renewable), transportation (railways, airports), smart cities, and utilities. These sectors require robust networking equipment that can withstand challenging physical conditions while ensuring continuous, secure communication for critical operations.

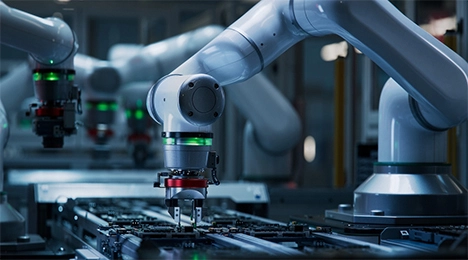

Why are Industrial Switches critical for Industrial IoT (IIoT)?

Industrial switches play a vital role in IIoT because they enable seamless and reliable communication between industrial devices, sensors, and control systems. By offering real-time data transmission, industrial switches support automation, predictive maintenance, and monitoring in various applications like robotics, remote monitoring, and machine-to-machine communication, which are central to IIoT.

What is the difference between managed and unmanaged Industrial Switches?

Managed industrial switches offer greater control over the network, allowing for features like VLANs, SNMP monitoring, redundancy protocols, and network security. They can be configured and managed remotely, providing advanced network management. Unmanaged switches, on the other hand, are plug-and-play devices with no configuration options, ideal for simpler, smaller networks with lower complexity.

How do Industrial Switches handle network redundancy?

Industrial switches typically support various redundancy protocols, like STP (Spanning Tree Protocol), RSTP (Rapid Spanning Tree Protocol), and MRP (Media Redundancy Protocol), ensuring network reliability and minimizing downtime. In case of a link failure, these protocols allow the network to quickly reroute traffic, maintaining continuous communication in mission-critical applications.

Can Industrial Switches support Power over Ethernet (PoE)?

Yes, many industrial switches support Power over Ethernet (PoE), enabling them to deliver both data and power over a single Ethernet cable. This feature is especially useful for powering devices like IP cameras, wireless access points, and VoIP phones without needing separate power supplies, which simplifies installation and reduces costs.

What are the key considerations when choosing an Industrial Switch?

When selecting an industrial switch, key considerations include the type of environment (temperature, humidity, vibration), the required network speed (e.g., 1GbE, 10GbE), redundancy support, management features (for monitoring and control), PoE capabilities, and the number of ports. Additionally, it’s important to check for certification standards like UL, CE, and RoHS to ensure the switch complies with safety and environmental regulations.

What environmental conditions do Industrial Switches withstand?

Industrial switches are designed to operate in environments with extreme temperatures (typically ranging from -40°C to +75°C), high humidity, dust, shock, and vibration. They are also often rated for ingress protection (IP) against water and dust, ensuring they remain functional in challenging industrial environments, such as factory floors, outdoor installations, and control rooms.

Are Industrial Switches secure?

Yes, industrial switches come with advanced security features like VLANs, port security, access control lists (ACLs), and more to prevent unauthorized access. Managed industrial switches may offer additional features such as network monitoring, firewall capabilities, and encryption, ensuring secure data transmission and protection against potential cyber threats in industrial networks.

What protocols do Industrial Switches support?

Industrial switches typically support a range of protocols, including Ethernet, TCP/IP, Modbus, PROFINET, EtherNet/IP, and OPC UA. These protocols are vital for communication in industrial automation systems, enabling devices to exchange data efficiently and reliably in real-time.

What is the role of Industrial Switches in SCADA systems?

In SCADA (Supervisory Control and Data Acquisition) systems, industrial switches serve as the backbone for network communication. They connect different devices, such as sensors, control systems, and human-machine interfaces (HMIs), ensuring that data flows smoothly between all components. A reliable industrial switch is critical for SCADA systems that monitor and control industrial processes in real-time.

How do Industrial Switches improve network performance?

Industrial switches optimize network performance by reducing latency, improving bandwidth utilization, and ensuring reliable data transfer. Managed switches can prioritize traffic (Quality of Service or QoS), handle large volumes of data efficiently, and monitor network health to avoid congestion. This is especially important in time-sensitive industrial applications where real-time communication is crucial.

What is the maximum number of ports available in Industrial Switches?

The number of ports in an industrial switch can range from a few ports (e.g., 5-8 ports) to over 40 or even 48 ports for larger deployments. The port density required depends on the network’s scale and the number of devices that need to be connected. Industrial switches with higher port counts are typically used in large networks, such as manufacturing plants or city-wide infrastructure.

Can Industrial Switches support fiber optic connections?

Yes, industrial switches can support fiber optic connections, enabling long-distance, high-speed communication. Fiber optic connections are ideal for industrial networks that span large areas, like power grids, transportation systems, or large factories, offering high bandwidth and immunity to electromagnetic interference.

How do Industrial Switches help with network diagnostics?

Managed industrial switches come equipped with diagnostic tools like SNMP (Simple Network Management Protocol) for network monitoring, event logging, and performance analytics. These features help engineers and network administrators quickly identify and troubleshoot network issues, ensuring minimal downtime and maintaining optimal network performance.

Are Industrial Switches easy to maintain?

Yes, industrial switches are designed for easy maintenance, with features like remote monitoring, firmware updates, and diagnostic tools that help reduce the need for hands-on intervention. Managed switches, in particular, can be configured to alert administrators about network failures, allowing them to respond proactively before issues impact the system.

What is the lifespan of an Industrial Switch?

The lifespan of an industrial switch can range from 5 to 15 years, depending on the quality of the device, environmental conditions, and usage. High-quality switches with robust build standards and proper maintenance can last longer, while those in harsh conditions may require replacement sooner.

What certifications should an Industrial Switch have?

Key certifications for industrial switches include UL (Underwriters Laboratories) for safety, CE (Conformité Européene) for compliance with European standards, RoHS (Restriction of Hazardous Substances) for environmental safety, and IEC (International Electrotechnical Commission) for compliance with international electrical standards. These certifications ensure that the switch meets industry-specific safety, environmental, and performance standards.

How do Industrial Switches improve network reliability?

Industrial switches improve network reliability by providing features such as redundancy protocols (like RSTP or MRP), high-quality components designed for durability, and fault-tolerant designs that minimize the risk of network downtime. They also offer load balancing, traffic prioritization, and real-time monitoring to ensure the network performs optimally at all times.

What is the cost range of an Industrial Switch?

The cost of industrial switches varies depending on factors such as the number of ports, management features, environmental ruggedness, and advanced capabilities like PoE or fiber support. Basic unmanaged switches might cost around $100-$300, while managed industrial switches can range from $300 to several thousand dollars for high-end models with advanced features.

How do Industrial Switches support automation?

Industrial switches play a critical role in automation systems by providing reliable, high-speed connectivity between various devices like PLCs (Programmable Logic Controllers), SCADA systems, and robots. With their ability to handle large volumes of data and support real-time communication, these switches enable efficient and seamless operation of automated systems in industries like manufacturing and logistics.

What is the difference between Layer 2 and Layer 3 Industrial Switches?

Layer 2 industrial switches operate at the data link layer, handling MAC address-based forwarding of traffic within the same network. They are suitable for simple networks where devices need to communicate locally. Layer 3 industrial switches operate at the network layer and can perform routing functions, allowing them to forward traffic between different subnets or networks. Layer 3 switches are ideal for larger, more complex networks that require inter-network communication.

How do Industrial Switches enhance network scalability?

Industrial switches support network scalability by providing modular configurations and higher port densities. Managed switches, with features like VLANs and trunking, allow network administrators to segment and scale the network as the business grows. Additionally, industrial switches with fiber optic capabilities can connect distant network segments, further enhancing the scalability of large industrial networks.

Can Industrial Switches support wireless communication?

While traditional industrial switches are wired devices, many modern industrial switches come with integrated wireless capabilities or support for external wireless access points. These switches can provide connectivity for wireless devices like mobile tablets, wireless cameras, and remote sensors, offering flexibility for dynamic industrial environments where wired connections are impractical.

What is the role of Industrial Switches in edge computing?

In edge computing, industrial switches enable real-time data processing closer to the source, such as sensors or control systems. By providing low-latency communication, these switches help improve the speed and reliability of applications in industries like manufacturing, logistics, and energy, where immediate data processing is critical for decision-making and automation.

What are the power requirements for Industrial Switches?

Industrial switches typically operate on standard AC power (110V-240V), but many models also support DC power inputs, which are useful in industrial settings where DC power is more readily available. Some industrial switches, particularly PoE-enabled models, can also deliver power to connected devices over the same Ethernet cable, simplifying power management and reducing the need for separate power supplies.

How do Industrial Switches support fault tolerance?

Industrial switches support fault tolerance by implementing network redundancy features such as ring topology, MRP (Media Redundancy Protocol), and RSTP (Rapid Spanning Tree Protocol). These features ensure that if a network link fails, the traffic can quickly be rerouted via alternate paths, minimizing downtime and ensuring the continued operation of critical systems.

Can Industrial Switches be integrated with cloud services?

Yes, many industrial switches support integration with cloud-based management systems, allowing remote monitoring, configuration, and diagnostics via cloud platforms. This integration is beneficial for large-scale operations and distributed networks, enabling real-time visibility and management of industrial devices from anywhere in the world.

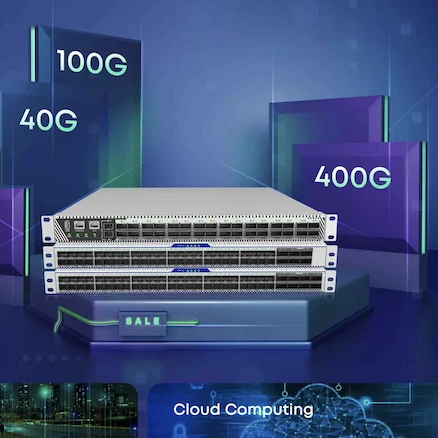

How do Industrial Switches ensure high-speed data transmission?

Industrial switches are designed with high-performance hardware and support advanced features like QoS (Quality of Service) and traffic prioritization to ensure that critical data is transmitted without delay. They also support higher bandwidth connections, such as Gigabit Ethernet (GbE) or 10GbE, and fiber optic links for fast, reliable data transfer over long distances in industrial networks.

Are Industrial Switches compatible with existing IT infrastructure?

Yes, most industrial switches are compatible with existing IT infrastructure, as they use standard networking protocols like Ethernet and TCP/IP. They can be integrated into corporate IT networks, connecting with office networks, data centers, and cloud services. However, industrial switches may also support specific protocols and features tailored for industrial environments, which might require some network configuration adjustments.

What is the importance of electromagnetic compatibility (EMC) in Industrial Switches?

Electromagnetic compatibility (EMC) is critical for industrial switches, as they must operate without causing or being affected by electromagnetic interference (EMI). Industrial environments often have machinery and equipment that generate electromagnetic noise, which can disrupt network communication. EMC-certified switches ensure that the device operates smoothly and reliably even in the presence of such interference.

How do Industrial Switches handle network traffic management?

Industrial switches manage network traffic through various techniques, such as load balancing, traffic shaping, and quality of service (QoS) prioritization. These features allow switches to allocate bandwidth efficiently, prevent congestion, and ensure that time-sensitive data, like control commands or video feeds, are given priority over less critical traffic, ensuring optimal network performance in industrial environments.

Can Industrial Switches be remotely managed?

Yes, managed industrial switches can be remotely configured, monitored, and diagnosed through a variety of protocols, such as SNMP (Simple Network Management Protocol), web interfaces, or dedicated management software. Remote management is particularly useful in large, distributed networks where physical access to each device is difficult, allowing engineers to make changes or troubleshoot from any location.

How do Industrial Switches support safety and security in critical infrastructure?

Industrial switches enhance safety and security by supporting network segmentation (VLANs), user authentication, and access control lists (ACLs) to restrict access to sensitive data and devices. Managed switches often include built-in firewall capabilities and support for encryption, ensuring that data remains secure and that the network is protected from potential cyber threats or unauthorized access.

What is the role of Industrial Switches in predictive maintenance?

Industrial switches support predictive maintenance by providing reliable, real-time data transmission from sensors and monitoring devices to central control systems. By enabling continuous monitoring of equipment health, these switches help detect potential failures before they occur, reducing downtime and maintenance costs by allowing for proactive interventions and repairs.

What are some challenges when deploying Industrial Switches in harsh environments?

Deploying industrial switches in harsh environments presents challenges such as temperature extremes, physical vibrations, humidity, and dust. These environmental factors can affect the switch's performance and lifespan. To overcome these challenges, industrial switches are built with rugged enclosures, higher durability ratings (like IP65/IP67 for dust and water resistance), and components that can tolerate a wider temperature range, ensuring reliable operation in challenging conditions.

How do Industrial Switches handle network segmentation?

Industrial switches handle network segmentation by creating virtual LANs (VLANs) that divide a network into smaller, isolated segments. This segmentation improves network security by limiting access to sensitive data and devices, reduces congestion by managing traffic more effectively, and ensures better performance by minimizing unnecessary broadcast traffic in industrial networks.

What role do Industrial Switches play in automation systems?

Industrial switches are integral to automation systems, providing the necessary network infrastructure for devices like PLCs, sensors, and actuators to communicate. They ensure that real-time data from production lines, sensors, and other industrial equipment is transmitted reliably and without delays, which is essential for the smooth and efficient operation of automated manufacturing and process control systems.

How do Industrial Switches support disaster recovery?

Industrial switches support disaster recovery by offering features like redundant power supplies, dual network paths, and automatic failover protocols (e.g., MRP, RSTP). These features ensure that the network remains operational even in the event of hardware failures or environmental disruptions, minimizing downtime and enabling a quick recovery to normal operations.

Internet Data Center

Internet Data Center FAQs

FAQs Industry News

Industry News About Us

About Us Data Center Switch

Data Center Switch  Enterprise Switch

Enterprise Switch  Industrial Switch

Industrial Switch  Access Switch

Access Switch  Integrated Network

Integrated Network  Optical Module & Cable

Optical Module & Cable

.webp)

Call us on:

Call us on:  Email Us:

Email Us:  2106B, #3D, Cloud Park Phase 1, Bantian, Longgang, Shenzhen, 518129, P.R.C.

2106B, #3D, Cloud Park Phase 1, Bantian, Longgang, Shenzhen, 518129, P.R.C.